- Call us: (+30) 27510 29165-29730

- Working Hours: Mon.-Wed.-Sat. 8.00–14.00, Tue.-Thu.–Fri. 8.00–14.00 & 17:30-20:30

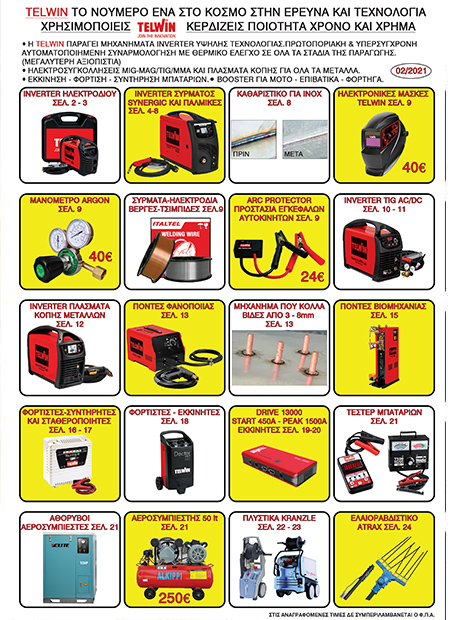

TELWIN WELDING INVERTER 180A TECNICA 211 / S + GIFT ELECTRONIC MASK TRIBE (81622)

The new generation of Inverter welds presents spectacular advantages over conventional welds.

Its main advantage is the way of welding. Conventional welding created an arc when welding with alternating current which resulted in high demand for electricity, uneven gauze, electrode adhesions on the metal.

Inverter welds convert AC power into direct current and this results in low power consumption, smooth arc start, uniform gauze without splashes.

High reliability welding.

Low power consumption.

Small size.

Low weight for easy transport and use outdoors.

Smooth and easy start of the arc.

Stable welding function for uniform gauze, without splashes.

Protection against input voltage fluctuations.

Possibility of welding BASIC-RUTILE-INOX electrodes.

Thanks to the high quality of power generation (Low Distortion Quality System) it has the ability to burn an electrode up to 4.0mm.

Arc Force, Hot Start, Anti-Stick systems now belong to the basic equipment of the TELWIN family. Arc Force: Automatic current calibration during gluing.

Hot Start: Prevents the flame from going out when the electrode is in contact with the gluing object.

Anti-Stick: Prevents the electrode from sticking to the sticking point

TELWIN WELDING INVERTER 180A TECNICA 211 / S + GIFT ELECTRONIC MASK TRIBE (81622)

| > Yield 180 A. |

| > Electrode max 4.00 mm |

| > Weight 6.6 kg |

| > Wire max. 1.20 mm |

| > Voltage 230 V |

No further info found for this product

Fill-in the following form!